How to: Terminate a Shielded Toolless Keystone Jack

Written by Don Schultz, trueCABLE Senior Technical Advisor, Fluke Networks Copper/Fiber CCTT, BICSI INST1, INSTC, INSTF Certified

“Do the task right the first time.” This well-known mantra applies to the world of Ethernet as much as any other. Have you ever seen a “spaghetti monster” cable installation before? I have, and more than once. What caused all the mayhem? Poor planning. There is a secret weapon to help avoid this. It is even easy to create and use.

It is called a “permanent link.” How do I get one of those? Well, you will need an Ethernet keystone jack to pull it off! The other end of the permanent link will be yet another keystone jack or a patch panel. For the DIY installer, this might be a new concept. Many first time installers will put RJ45 connector plugs onto both ends of the cable. Now, this will work, but it will restrict your installation in one key way: flexibility. It is also the potential birth of the “spaghetti monster”. Wouldn’t it be nice if you could relocate your equipment around the room by merely buying different lengths of Ethernet patch cable to plug into your wall jacks?

For shielded Ethernet cable, it bears mentioning that putting RJ45 plugs on can be a bit frustrating. Thicker outdoor shielded Ethernet cable can amplify frustration unless you have a great deal of practice.

Another item worth mentioning is that permanent links change up permitted lengths. You get more flexibility, but there are a few more rules to be aware of as outlined in Maximum Ethernet Cable Length.

Professional installers and DIY folks will benefit from this article and video combination. Not every keystone jack is alike, from manufacturer to manufacturer. Shielded Ethernet cable termination also requires additional attention to detail, as grounding of the cable shield is critical to avoid ground loops or other maladies. For these maladies and how to avoid them, take a look at How to Fix a Ground Loop.

This blog is a companion to the video below. I strongly recommend you watch the video and read the blog. Both mediums bring something to the table.

This blog focuses on our toolless Cat6 shielded keystone jack. These instructions are suitable for any of our shielded toolless keystone jacks, regardless of Category. Just be aware that Cat5e cable does not have a center spline, and the rest is the same.

Nothing is truly toolless, so let’s get that out of the way first.

You will need some tools, just not a punch down impact tool

Two must haves, and one really nice to have…

Required tools:

Nice to have, and truly unique:

- trueCLOSE parallel jaw pliers

Alternatively, if you have channel lock pliers on hand, you can use those to close the keystone jack lid. Cat5e cable is pretty easy to snap shut inside of a toolless keystone jack, but Cat6 and Cat6A, with their thicker conductors, will require more finger and hand strength than you may expect. I often cannot close the jack housings, especially with my teenie hands...

For this demonstration, I am using our Cat6 Direct Burial Shielded cable -- in black.

Let’s get to it!

Start by stripping off about 2 ½” of the cable jacket. You want to score it, not cut through it. Then, pop open the jacket by bending a couple of times at the score.

Now, cut off the ripcord. Tip...if you see the cable shield has been cut by the strip tool, you might have nicked a conductor!

If you accidentally cut through the cable shield and nicked a conductor, you will need to start over. See What Does a Bad Termination Look Like? for pictures of what to look out for.

Carefully cut off excess cable shield, but leave about ½”. Fold the cable shield backward over the cable jacket. Wrap the drain wire around the shield. Make it neat!

In this step, if you are working with a direct burial Ethernet cable, you will need to cut off the water proof fabric tape entirely (not shown). This is also an excellent time to inspect the conductors again for nicks at the cable jacket edge.

Cut each “wing” of the spline, resting the clippers near the cable jacket and at a downward angle. Make four cuts. Again, skip this for Cat5e.

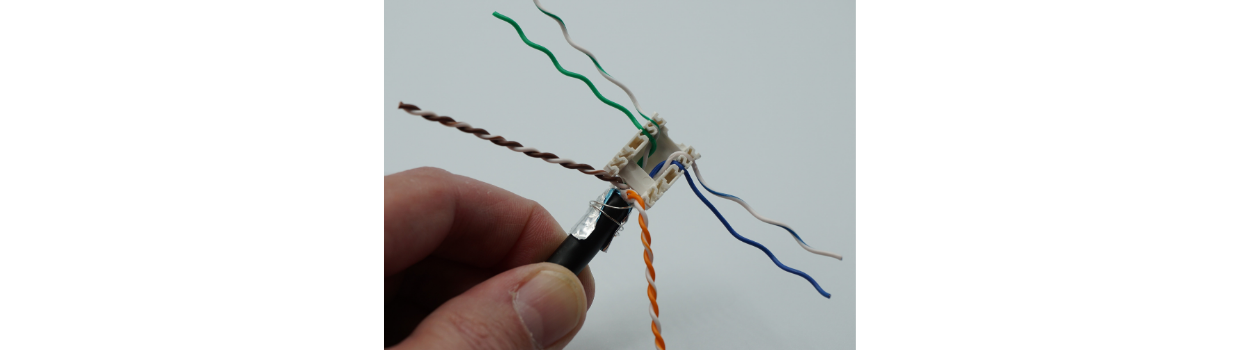

Twist to remove the spline. Insert conductors into the holder cap and using a piece of cable jacket to untwist the conductors.

- Take a look at the color sequence on the sides of the conductor cap. You will notice the “top” sequence is for T568A, and the bottom is T568B. I am using “B” for this.

- Now, look at your cable and how the pairs are oriented. Place the pairs into an orientation that lend themselves to minimal cross-over.

- Place the blue and green pairs first into the conductor cap, under the bar.

- Slide the conductor cap down to the cable jacket and raise the two rear (brown and orange) pairs upward so they will be above the bar. Get the conductor cap as close as reasonably possible to the cable jacket as shown.

Blue and green pairs seated.

- Always begin with the green and blue pairs.

- Work on one pair at a time!

- Only untwist the pair as much as necessary to get down to the conductor cap. Excessive pair untwist will ruin your termination.

All pairs seated. This is the T568B sequence...

All pairs seated. This is the T568B sequence...

- The distance from the last twist in the pair to where the individual conductor wires seat into the conductor cap cannot exceed ½”.

- The closer the last twist is to where the wires actually sit, the better the performance.

Flush cut the conductors off, so they are even with the cap housing. Next raise up the keystone jack lid, and place the conductor holder into the jack

- The conductor holder cap will only go in one way

- There is a molded in arrow at the front of the cap, on top, that should be pointed at the RJ45 port on the jack

Snap! Close the jack lid. If you do not have the finger/hand strength, try our trueCLOSE parallel jaw pliers.

Insert the zip tie through the metal channel, and tightly cinch it down. Flush cut off the excess. And you're done! It's all ready to insert into a wall plate or shielded keystone jack patch panel.

Well, there you have it—a ready to go keystone jack termination. Now you can plug a patch cable into the RJ45 port on the jack and gain a degree of flexibility you may not have had previously.

HAPPY NETWORKING!!

WAIT! Did something go wrong? Check out What Does a Bad Termination Look Like?

trueCABLE presents the information on our website, including the “Cable Academy” blog and live chat support, as a service to our customers and other visitors to our website subject to our website terms and conditions. While the information on this website is about data networking and electrical issues, it is not professional advice and any reliance on such material is at your own risk.