Payment methods accepted

Shop Our Best-Selling Products.

Ethernet Cable

Our high-quality bulk Ethernet cables are available in Cat5e, Cat6, and Cat6A. Manufactured with solid, bare-copper conductors for better conductivity and flexibility. In our collection, you’ll find several styles of Ethernet supplies for various applications.

Shop All Ethernet Cable-

Cat6 Riser Ethernet Cable|Unshielded

$133.99 - $175.99 View Product -

Cat6 Direct Burial Ethernet Cable|Shielded

$156.74 - $236.99 View Product -

Cat6A Riser Ethernet Cable|Shielded

$284.04 - $298.99 View Product -

Cat6 Riser Ethernet Cable|Shielded

$175.99 - $236.99 View Product -

Cat6A Riser Ethernet Cable|Unshielded

$247.99 View Product -

Cat6 Outdoor Ethernet Cable|Shielded

$154.99 - $226.99 View Product

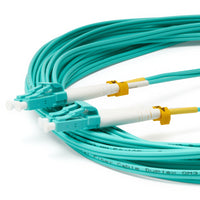

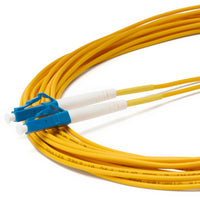

Fiber Optic

Our fiber optic supplies enable you to create a robust infrastructure that supports seamless communication, efficient data transfer, and uninterrupted productivity. Experience the transformative power of fiber optics and propel your business forward.

Shop All Fiber Optics-

LC to LC UPC Duplex OM4 | MM OFNR

$8.49 - $191.49 View Product -

Click Cleaner LC/MU

$17.99 - $87.29 View Product -

LC to LC UPC Duplex OS2 | SM OFNR

$7.79 - $86.79 View Product -

LC to LC UPC Duplex OM3 | MM OFNR

$8.45 - $94.49 View Product -

Click Cleaner SC/ST/FC

$17.99 - $87.29 View Product -

LC to LC UPC Simplex OS2 | SM OFNR

$6.09 - $52.29 View Product

Coaxial Cable

Our high-quality coax cables are manufactured with solid, bare copper conductors, the ideal material for data transmission, low voltage and satellite installations. Our bulk coaxial cable has been sweep tested up to 3GHz.

Shop All Coaxial Cables-

RG6 Quad Shield Riser Coaxial Cable

$120.99 - $172.99 View Product -

RG6 Quad Shield Outdoor Coaxial Cable

$131.99 - $183.99 View Product -

RG6 Dual Shield Riser Coaxial Cable

$106.99 - $148.99 View Product -

RG6 Dual Shield Outdoor Coaxial Cable

$109.24 - $158.99 View Product

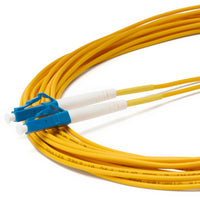

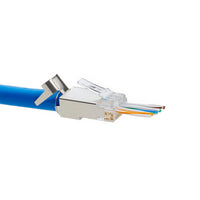

RJ45 Connectors

All our connector styles are thoroughly tested and proven in the field by real installers to work with our cable and tools as a system. Ease of use is the name of the game, streamlining your installation whether you are a beginner or professional.

Shop All RJ45 Connectors-

Cat6/6A Pass Through RJ45 Connectors|Shielded

$18.99 - $83.99 View Product -

Cat6/6A Pass Through RJ45 Connectors|Unshielded

$16.99 - $33.99 View Product -

Cat6/6A Standard RJ45 Connectors|Unshielded

$6.99 - $30.99 View Product -

Cat6A Extra Large Pass Through RJ45 Connectors|Unshielded

$18.99 - $35.99 View Product -

Cat6A Field Term Plug|Shielded

$16.99 - $68.99 View Product -

Cat5e Pass Through RJ45 Connectors|Unshielded

$14.99 - $30.99 View Product

Patch Panels

Choose from top-rated patch panels ready for data centers, offices, industrial settings, and much more! Our high-quality patch panels known for simplicity and reliability come in both shielded and unshielded variations, ready for any installation!

Shop All Patch Panels-

Shielded Patch Panel, 24 Port, 1U, Blank Modular

$29.99 View Product -

Unshielded Patch Panel, 24 Port, 1U, Staggered Blank Modular

$59.99 View Product -

Shielded Ethernet Patch Panel Bond & Ground Extension Wire Adapter

$24.99 View Product

Keystone Jacks

We offer a broad range of keystone jacks for in-wall and patch panel applications. They are component rated for more stable speeds and durable terminations. Our keystone jacks are tested with our cables as a system on our Fluke DSX-8000.

Shop All Keystone Jacks-

Cat6 Punch Down Keystone Jack|Unshielded

$20.99 - $66.99 View Product -

Single Gang Wall Plates

$3.99 - $12.99 View Product -

Cat6A Toolless Keystone Jack|Shielded

$10.99 - $52.99 View Product -

Cat6A Punch Down Keystone Jack|Unshielded

$29.99 - $106.99 View Product -

Cat6 Toolless Keystone Jack|Unshielded

$4.99 - $19.99 View Product -

Cat6 Toolless Keystone Jack|Shielded

$8.99 - $43.99 View Product

Ethernet Couplers

We offer a broad range of Ethernet cable couplers for in-wall and patch panel applications. Shielded, unshielded, keystone jack, and in-line in every common ANSI/TIA 568 recognized Category. Our Cat6 Ethernet couplers are tested with every type of bulk Ethernet cable we sell as a system with our Fluke DSX-8000.

Shop All Ethernet Couplers-

Single Gang Wall Plates

$3.99 - $12.99 View Product -

Cat6 Waterproof Couplers|Shielded

$15.99 - $37.99 View Product -

Cat6A Waterproof Couplers|Shielded

$19.99 - $41.99 View Product -

Cat6 Keystone Jack Coupler|Unshielded

$7.99 - $39.99 View Product -

Cat6A Keystone Jack Coupler|Unshielded

$9.99 - $48.99 View Product -

Cat6 Inline Coupler|Unshielded

$7.99 - $39.99 View Product

Tools

You rely on your tools to perform. We designed ours to last a lifetime and backed them with a Forever Warranty. We guarantee quality construction, precision and value. Streamline your job and pick up a set of quality tools for your bag.

Shop All Tools-

All-In-One Crimp and Termination Tool

$56.99 View Product -

Cable Stripping & Cutting Tool

$14.99 View Product -

Flush Cutter

$9.99 View Product -

EZ Termination Keystone Jack Tool

$49.99 View Product -

Parallel Crimping Pliers

$29.99 View Product -

110 Impact Tool

$39.99 View Product

Shop Our Popular Product Groups

We take time to listen to our customers when we test and develop our low-voltage products to work seamlessly together as a system.

Shop AllQuality Certifications

We want to provide you, our customer, with the highest quality products. By doing so, we put our products through rigorous internal and external testing.

Read More About Our Quality Certifications

Welcome to the Cable Academy

Looking for the best Ethernet and Fiber Optic cable supplies? Our online store has you covered. Not only that, but we also offer expert customer support.

Check out our in-depth blogs, which offer expert guidance in understanding the low-voltage industry.

-

Apr 25, 2024Why Is VIOLET In My Fiber Cabling Installation?

Apr 25, 2024Why Is VIOLET In My Fiber Cabling Installation?- Fiber Patch Cables

- OM4

- Violet

This guide examines the introduction of violet jacket coloring for OM4 fiber optic cables. It covers the legacy use of orange, aqua and yellow colors, issues that arose from OM1/OM2 and OM3/OM4 cables using the same colors, and how violet aims to distinguish OM4 to prevent inadvertent mixing and potential performance problems.Read More -

Apr 18, 2024RG59 vs RG6: Key Differences And Which Coaxial Cable Is Best For YouRG59 and RG6 coaxial cables look alike but have key differences. Choosing the wrong one can mean poor performance. This guide breaks down when to use each type based on bandwidth needs, shielding effectiveness, applications like internet/TV, and more. Get the facts to make the right coax cable selection.Read More

Apr 18, 2024RG59 vs RG6: Key Differences And Which Coaxial Cable Is Best For YouRG59 and RG6 coaxial cables look alike but have key differences. Choosing the wrong one can mean poor performance. This guide breaks down when to use each type based on bandwidth needs, shielding effectiveness, applications like internet/TV, and more. Get the facts to make the right coax cable selection.Read More -

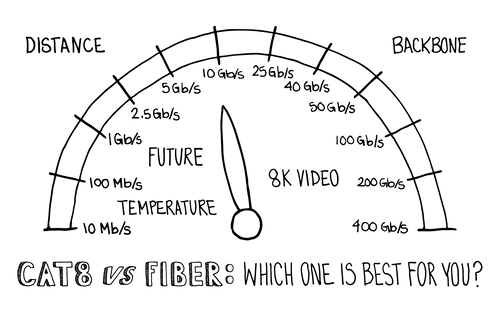

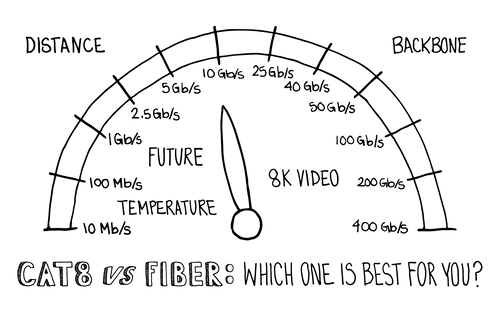

Apr 12, 2024Cat8 vs Fiber: Which one is best for you?

Apr 12, 2024Cat8 vs Fiber: Which one is best for you?- cat8

- Fiber Optic

- Fiber Optic Benefits

The debate between Cat8 and fiber optic cables is more relevant than ever in today's fast-paced technological landscape. Cat8, the latest copper cable evolution, boasts high-speed connectivity, while fiber optics showcase unparalleled capacity for long-distance, high-speed data transmission. This comparative analysis explores the specific capabilities, cost implications, and installation challenges of each technology, empowering you to make an informed decision tailored to your unique networking requirements.Read More -

Apr 4, 2024Improve Your Home WiFi: When to Use Extenders vs Access Points for Signal Issues

Apr 4, 2024Improve Your Home WiFi: When to Use Extenders vs Access Points for Signal Issues- bulk cable

- DIY

- Ethernet Cable

In this third part of the series “How to Boost Your WiFi Signal”, we are going to cover the most troublesome device of them all, the evil and despised range extender. We will talk about using stand alone WiFi Access Points (WAPs) to overcome challenges in certain environments instead of using a range extender.Read More

WHAT OUR CUSTOMERS ARE SAYING:

Read More ReviewsEasy, fast, and reliable

“I checked several websites for direct burial CAT6A cable but most had incomplete information like whether or not it was in stock, what brand it was, how much shipping costs were, and so on. When I came across the trueCABLE site all of that disappeared and everything I needed to decide on a purchase and then some was readily available. The search was quick and efficient, giving me pictures and descriptions of the results. One click and the page showed the cable, a summary of its specs and capabilities, the price including quantity discounts, the estimated delivery date, a link to a full spec sheet, colors that were available, and my favorite, links to accessories that were compatible with the cable! Right there in front of me was everything I needed to make a decision on the cable, plus several connectors which fit the cable as well as crimp tools for those connectors. What a great website, no more spending hours doing research, emailing for pricing and delivery details, or guessing about this or that spec/feature because the web designer didn't bother to include the information.”

- J CooperEXACTLY what I needed for a fraction of the cost!

I've been such a longtime supporter of trueCABLE that I've been so happy to see fiber optic products ramping up! Can't wait for their armored/outdoor line! There prices are just so much better than anyone else, especially for the quality of their products. These duplex cables were exactly what I was looking for. Good quality, great price.

- Danny Z.trueCABLE always comes through!

Needed data cable on site within a short window and trueCABLE made it happen. They’re my go-to for all control wiring needs. Great selection, great service, what else could you ask for?

- AnonymousHappy DIY Customer

“Your company is outstanding in many ways that seal my support for you. Pricing on many products is significantly better than your competitors...especially when your characteristics exceed theirs. Your cable terminations are easy to use for a better price. Yes, I could spend double the cost on terminators and Yes, they look pretty, but yours will work simply fine. Your products also allow me to future proof for technology that will be in place for a long, long time. Your academy of information is SPECTACULAR. I tell all my friends the source of technical procedures and performances every detail has on proper installations. Thank you for your continued support of the DIY and others."

-William H.trueCable? Of course!

“I was skeptical at first. I don't do garbage cable. PERIOD. EVER. But it's hard to find reputable sellers as a home/small business guy that aren't trying to pass off trash cable and hardware as a "quality" product. I like trueCABLE because of their simpler approach to offering solutions. Prices are about what you expect but it's legit QUALITY stuff. trueCABLE’s site makes the specs and sizes very clear which helps you to pair up cables and connectors. Also... Their products are ANSI/ETL listed. Certified. This is very important and they nailed that down. I just bought a new house! So I'm installing some hardcore Aruba wifi gear! I needed excellent cable for POE+ access points. So I bought a 1000ft reel of Cat6A CMR 750MHz, modular connectors (MDPTRJ45_50pc), and a really handy cable caddy for the reel. I'm VERY happy with the results. Shopping at their site was easier and seemed to be cheaper than on Amazon. Shipping was actually LIGHTNING FAST, too. Was very surprised by that! I'm grateful to have finally found a reliable provider of cabling gear that I can now have as a go-to. Thanks, trueCABLE! Ya made my freakin' day!”

- Cory K.Buy Ethernet and Fiber Cable at Our One-Stop Low-Voltage Supply Store

trueCABLE is shaking up how Ethernet cable, fiber optics, and network cable suppliers get things done. Our goal is to provide reliable, high-quality network cabling, connecting hardware, and Ethernet supplies to you quickly and directly from our high-service factory. As industry experts, we’ve created and manufactured our own line of Ethernet cables, coaxial cables, connectors, fiber optics, and various tools. Everything we sell has been tested for performance and compatibility, making us an end-to-end solution provider. Put your trust in trueCABLE as your one-stop shop for low-voltage and fiber optic networking supplies.

We offer bulk purchasing options on all types of cable. Supplies include variations of Cat6A, Cat6, and Cat5e for indoor and outdoor applications. Buy ethernet cable for your next job or business through trueCABLE—your reliable low voltage supplier—today.